|

Bilayer

Actuators | Bilayers

Moving Rigid Plates | Self-Assembling

Boxes | MicroRobot Arm | Moving

Silicon Plates

Moving Electrochromic

Device on Silicon | Micro-Origami | Out-of-Plane Volume Change

Micromuscle AB is now commercializing this

technology for medical applications.

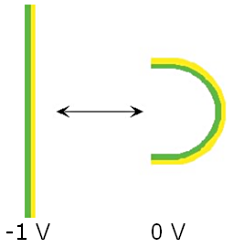

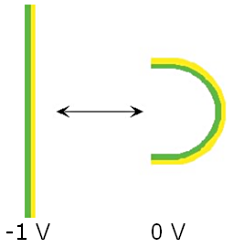

If a film of

volume-changing material (e.g. the conjugated polymer) is attached to a film that does not change

volume (such as a metal electrode or a film of an inert polymer), then this bilayer will bend.

In the schematic below, the polymer (we use polypyrrole, PPy) is shown as green and the second layer

(we uses gold, which then also serves as the working electrode) is shown as yellow. The volume of

the polymer is changed by an applied electrochemical potential. If a film of

volume-changing material (e.g. the conjugated polymer) is attached to a film that does not change

volume (such as a metal electrode or a film of an inert polymer), then this bilayer will bend.

In the schematic below, the polymer (we use polypyrrole, PPy) is shown as green and the second layer

(we uses gold, which then also serves as the working electrode) is shown as yellow. The volume of

the polymer is changed by an applied electrochemical potential.

|

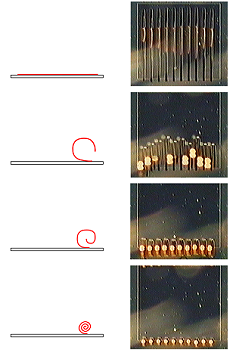

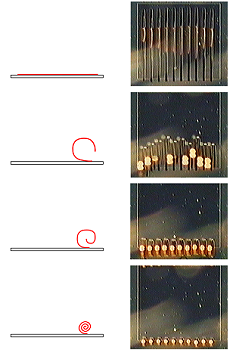

Here are some PPy/Au bilayers

microfabricated on a silicon substrate (using

surface micromachining and the differential adhesion method (link to patent),

shown looking straight down from overhead. I made these devices while I was at Linköping

University in Sweden, working with Prof. Olle Inganäs. The

bilayers are 1 mm long and 30 µm wide, and they are attached on the bottom edge. They are shown going

from straight to curled up. The cartoons on the left show side views of what is happening in the photographs.

The entire wafer is immersed in an aqueous electrolyte (0.1 M NaDBS) and serves as the working electrode; the

counter and reference electrodes are not shown. Here are some PPy/Au bilayers

microfabricated on a silicon substrate (using

surface micromachining and the differential adhesion method (link to patent),

shown looking straight down from overhead. I made these devices while I was at Linköping

University in Sweden, working with Prof. Olle Inganäs. The

bilayers are 1 mm long and 30 µm wide, and they are attached on the bottom edge. They are shown going

from straight to curled up. The cartoons on the left show side views of what is happening in the photographs.

The entire wafer is immersed in an aqueous electrolyte (0.1 M NaDBS) and serves as the working electrode; the

counter and reference electrodes are not shown.

For further information see:

E. Smela, Olle Inganäs, and Ingemar Lundström, "Controlled folding of micrometer-size structures," Science, 268 (23 June), 1735-1738, 1995.

Photos in the figure are from E. Smela, Olle Inganäs, and Ingemar Lundström,

“Controlled folding of micrometer-size structures," Science, 268 (23 June), 1735-1738,

1995.

|

The videos below are all in real time. The actuators move from completely flat to

fully curled and back (to/from fully oxidized to/from fully reduced) in about 1 second (the PPy is ~0.5

µm thick).

|

|

To see a video of these

bilayers in action,

double-click on the image on the left

QuickTime

Format. File

size is 3MB. Quicktime Player

required for viewing.

You can download a free player

HERE. |

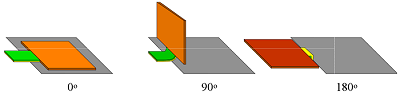

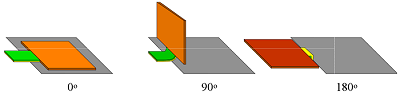

Bilayers by themselves simply curl up, but a bilayer attached to a s

ubstrate, such as a silicon wafer, can be used as a hinge, for example to

rotate a rigid plate out of the plane of the wafer. These devices were also

described in the Science 1995 publication.

|

|

For a Flash animation of a plate rotating (kindly

made by Peter Warkentin), click here (this will take you off of my site but open in a separate page).

To see a video of such plates, microfabricated on Si, moving, double-click the image on

the left, or click the play button. In this video, the plates are 150 µm on each side,

and the hinges are 30 x 30 µm. Hinges of that size were also able to rotate plates that were

1 mm on a side – these bilayers are strong (for measurements on these actuators, see

JMEMS 1999.)

QuickTime Format.

File size is 3MB. Quicktime Player required

for viewing.

You can download a free player HERE. |

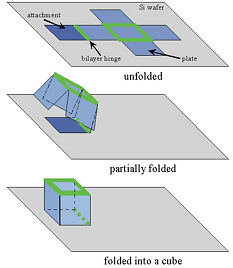

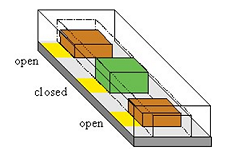

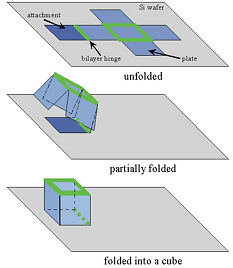

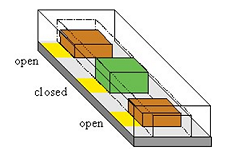

By using multiple hinges

and plates, more complex structures can be created. This is a schematic of a self-opening box.

(For MEMS people, follow this link for the processing sequence.) By using multiple hinges

and plates, more complex structures can be created. This is a schematic of a self-opening box.

(For MEMS people, follow this link for the processing sequence.)

QuickTime

Format.

File

size is 1MB.

Quicktime Player required

for viewing.

You can download a

free player HERE. |

|

For a video showing this self-folding box opening and

closing in real time, double-click the image below.

|

These 2 videos show boxes folding

around grains of sand.

QuickTime Format.

File sizes are 3MB each.

Quicktime Player required for viewing.

You can download a

free player HERE. |

|

|

This video shows a whole array of

self-folding boxes.

QuickTime Format.

File

size is 3MB.

Quicktime Player required

for viewing.

You can download a

free player HERE.

|

|

|

For further information, see:

- E. Smela, O. Inganäs, and I. Lundström, "Conducting polymers

as artificial muscles: challenges and possibilities,"

J. Micromech. Microeng., 3 (4), 203 (1993).

- E. Smela, O. Inganäs, Q. Pei, and I. Lundström, "Electrochemical

muscles: micromachining fingers and corkscrews,"

Adv. Mater., 5, 630-632 (1993).

- E. Smela, Olle Inganäs, and Ingemar Lundström, "Controlled

folding of micrometer-size structures,"

Science, 268 (23 June), 1735-1738, 1995.

- E. Smela, "Microfabrication of PPy microactuators and other conjugated

polymer devices,"

J. Micromech. Microeng., 9, 1-18 (1999).

- E. W. H. Jager, E. Smela, and O. Inganäs, "On-chip microelectrodes

for electrochemistry with moveable PPy bilayer actuators as working electrodes,"

Sens. Act. B, 56, 73-78 (1999).

- E. W. H. Jager, E. Smela, O. Inganäs, and I. Lundström,

"Polypyrrole microactuators,"

Synth. Met., 102 (1-3), 1309-1310 (1999).

- E. W. H. Jager, E. Smela, O. Inganäs, and I. Lundström,

"Applications of polypyrrole microactuators,"

Proc. SPIE's 6th Int. Symp. Smart Struc. Mater., Electroactive Polymer Actuators and Devices

(EAPAD), Newport Beach, CA, (SPIE), vol. 3669, edited by Y. Bar-Cohen, p. 377-384 (1-2 March, 1999).

- E. W. H. Jager, E. Smela, and O. Inganäs, "Microfabricating

conjugated polymer actuators,"

Science, 290, 1540-1545 (2000).

- E. W. H. Jager, E. Smela, and O. Inganäs, "Chapter 13, Microfabrication:

conjugated polymer actuators," in Communications Through Virtual Technology: Identity,

Community, and Technology in the Internet Age, Vol. 1,

edited by G. Riva and F. Davide (IOS Press, Amsterdam, 2001).

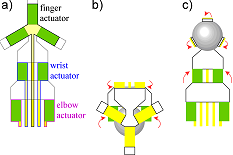

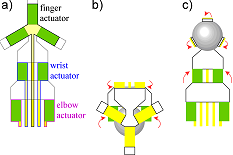

Edwin Jager, who was

co-supervised by me and Olle Inganäs at Linköping University, used this

approach to realize a micro-robot arm. It was able to pick up and reposition a

bead entirely under electrical control. Edwin Jager, who was

co-supervised by me and Olle Inganäs at Linköping University, used this

approach to realize a micro-robot arm. It was able to pick up and reposition a

bead entirely under electrical control.

To our knowledge, this is still

the only microfabricated robot arm ever made. You can see a video

here.

|

|

|

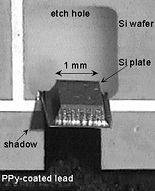

The example on the

left was made by surface micromachining,

and the rigid plates were polymeric. Silicon plates defines by bulk micromachining can also be made

(follow link for fabrication). After etching, this

plate was attached to the wafer only by the PPy/Au bilayer. In the figure the plate was rotated

out of the plane of the wafer by ~120 degrees. The example on the

left was made by surface micromachining,

and the rigid plates were polymeric. Silicon plates defines by bulk micromachining can also be made

(follow link for fabrication). After etching, this

plate was attached to the wafer only by the PPy/Au bilayer. In the figure the plate was rotated

out of the plane of the wafer by ~120 degrees.

Figure is from "Electrochemically Driven Polypyrrole Bilayers for Moving

and Positioning Bulk Micromachined Silicon Plates," E. Smela, M. Kallenbach, and J. Holdenried,

J. Microelectromechanical Systems, 8(4), 373-383, 1999. |

|

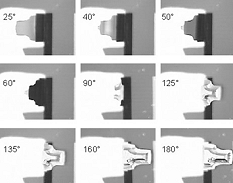

The sequence above shows

a second plate that has been held stationary at various angles by potentials at which the polymer is

intermediate between the fully oxidized and reduced states. The sequence above shows

a second plate that has been held stationary at various angles by potentials at which the polymer is

intermediate between the fully oxidized and reduced states.

Figure is from "Electrochemically Driven Polypyrrole Bilayers for Moving

and Positioning Bulk Micromachined Silicon Plates," E. Smela, M. Kallenbach, and J. Holdenried,

J. Microelectromechanical Systems, 8(4), 373-383, 1999.

|

This video shows this actuator

holding a couple of fixed positions.

|

These actuators are robust: they operate even when

they come into contact with macro-scale objects from the outside world.

|

For a video of earlier-generation bulk Si actuators,

click below.

|

For more information on these devices, see:

E. Smela, M. Kallenbach, and J. Holdenried, "Electrochemically Driven

Polypyrrole Bilayers for Moving and Positioning Bulk Micromachined Silicon Plates," J.

Microelectromechanical Systems, 8(4), 373-383, 1999.

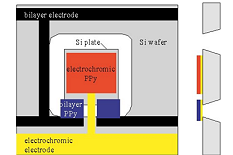

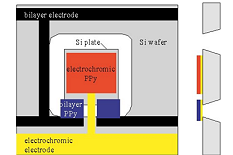

It is interesting to put an

active device on a moving silicon plate; an example is presented here of a moving electrochromic

device. It is interesting to put an

active device on a moving silicon plate; an example is presented here of a moving electrochromic

device.

Figure is from "A Microfabricated Movable

Electrochromic 'Pixel' Based on Polypyrrole,"

E. Smela, Advanced Materials, 11(16) 1343-1345, 1999. |

|

Polypyrrole

changes color as well as volume when the oxidation level changes. The outer electrodes (black in the

figure above) change the potential applied to the two PPy bilayer actuators (top to bottom), and a

second electrode (yellow in the figure above) changes the potential of the PPy film on the plate (side

to side, center row). Polypyrrole

changes color as well as volume when the oxidation level changes. The outer electrodes (black in the

figure above) change the potential applied to the two PPy bilayer actuators (top to bottom), and a

second electrode (yellow in the figure above) changes the potential of the PPy film on the plate (side

to side, center row).

Figure is from "A Microfabricated Movable Electrochromic 'Pixel' Based on

Polypyrrole," E. Smela, Advanced Materials, 11(16) 1343-1345, 1999. |

For a video showing this device in action,

click below.

|

|

For further information, see:

E. Smela, "A Microfabricated Movable Electrochromic

'Pixel' Based on Polypyrrole," Advanced Materials,

11(16) 1343-1345, 1999.

QuickTime Format.

File size is 3MB.

Quicktime Player required for viewing.

You can download a

free player HERE. |

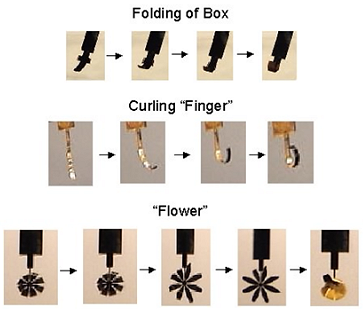

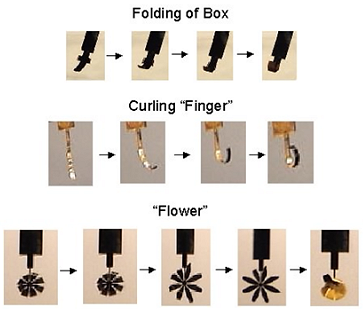

The idea of turning 2D shapes into micro-scale 3D structures by

folding is an interesting one, since microfabrication is typically limited to 2D. However, these

structures are usually manually folded, or folded all at once using e.g. solder. To control but automate

the folding step, one can use PPy/Au bilayer hinges, as shown below for simple structures made from

Kapton substrates. The idea of turning 2D shapes into micro-scale 3D structures by

folding is an interesting one, since microfabrication is typically limited to 2D. However, these

structures are usually manually folded, or folded all at once using e.g. solder. To control but automate

the folding step, one can use PPy/Au bilayer hinges, as shown below for simple structures made from

Kapton substrates.

Follow this link for the fabrication sequence.

This work was done by Yingkai Liu and

Hyo “Lance” Oh.

For a video of the

“flower”,

double-click below.

QuickTime

Format.

File sizes are 3MB each.

Quicktime Player required for viewing.

You can download a

free player HERE. |

|

For a video of a hand moving a hair

(and then dropping it), double-click below.

|

The bending bilayers above all made use of the

in-plane strain, which is approximately 3%. The out-of-plane strain is

much greater, about 30%. We are exploring the possibility of using this to

fabricate pumps and valves. The bending bilayers above all made use of the

in-plane strain, which is approximately 3%. The out-of-plane strain is

much greater, about 30%. We are exploring the possibility of using this to

fabricate pumps and valves.

For further information, see:

E. Smela and Nikolaj Gadegaard, "Volume change in polypyrrole

studied by atomic force microscopy," J. Phys. Chem. B, 105 (39) 9395-9405, 2001.

E. Smela and Nikolaj Gadegaard, "Surprising volume change in PPy(DBS): an

atomic force microscopy study," Advanced Materials, 11 (11) 953-7, 1999.

|

If a film of

volume-changing material (e.g. the conjugated polymer) is attached to a film that does not change

volume (such as a metal electrode or a film of an inert polymer), then this bilayer will bend.

In the schematic below, the polymer (we use polypyrrole, PPy) is shown as green and the second layer

(we uses gold, which then also serves as the working electrode) is shown as yellow. The volume of

the polymer is changed by an applied

If a film of

volume-changing material (e.g. the conjugated polymer) is attached to a film that does not change

volume (such as a metal electrode or a film of an inert polymer), then this bilayer will bend.

In the schematic below, the polymer (we use polypyrrole, PPy) is shown as green and the second layer

(we uses gold, which then also serves as the working electrode) is shown as yellow. The volume of

the polymer is changed by an applied  Here are some PPy/Au bilayers

microfabricated on a silicon substrate (using

Here are some PPy/Au bilayers

microfabricated on a silicon substrate (using

By using multiple hinges

and plates, more complex structures can be created. This is a schematic of a self-opening box.

(For MEMS people, follow this link for the

By using multiple hinges

and plates, more complex structures can be created. This is a schematic of a self-opening box.

(For MEMS people, follow this link for the  Edwin Jager, who was

co-supervised by me and Olle Inganäs at Linköping University, used this

approach to realize a micro-robot arm. It was able to pick up and reposition a

bead entirely under electrical control.

Edwin Jager, who was

co-supervised by me and Olle Inganäs at Linköping University, used this

approach to realize a micro-robot arm. It was able to pick up and reposition a

bead entirely under electrical control.  It is interesting to put an

active device on a moving silicon plate; an example is presented here of a moving electrochromic

device.

It is interesting to put an

active device on a moving silicon plate; an example is presented here of a moving electrochromic

device. Polypyrrole

changes color as well as volume when the oxidation level changes. The outer electrodes (black in the

figure above) change the potential applied to the two PPy bilayer actuators (top to bottom), and a

second electrode (yellow in the figure above) changes the potential of the PPy film on the plate (side

to side, center row).

Polypyrrole

changes color as well as volume when the oxidation level changes. The outer electrodes (black in the

figure above) change the potential applied to the two PPy bilayer actuators (top to bottom), and a

second electrode (yellow in the figure above) changes the potential of the PPy film on the plate (side

to side, center row). The idea of turning 2D shapes into micro-scale 3D structures by

folding is an interesting one, since microfabrication is typically limited to 2D. However, these

structures are usually manually folded, or folded all at once using e.g. solder. To control but automate

the folding step, one can use PPy/Au bilayer hinges, as shown below for simple structures made from

Kapton substrates.

The idea of turning 2D shapes into micro-scale 3D structures by

folding is an interesting one, since microfabrication is typically limited to 2D. However, these

structures are usually manually folded, or folded all at once using e.g. solder. To control but automate

the folding step, one can use PPy/Au bilayer hinges, as shown below for simple structures made from

Kapton substrates.  The bending bilayers above all made use of the

in-plane strain, which is approximately 3%. The out-of-plane strain is

much greater, about 30%. We are exploring the possibility of using this to

fabricate pumps and valves.

The bending bilayers above all made use of the

in-plane strain, which is approximately 3%. The out-of-plane strain is

much greater, about 30%. We are exploring the possibility of using this to

fabricate pumps and valves.