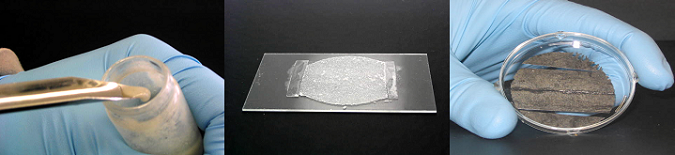

Dielectric Elastomer Actuators Background | Compliant Electrodes | PDMS as an Elastomer | Patterning PDMS Films | Modeling DEAs are in the family of electronic electroactive polymers (EAPs). Ron Pelrine and Roy Kornbluh of SRI pioneered the dielectric elastomer actuator (DEA) technology on the macro-scale, taking it from proof of concept to a wide range of devices, from speakers to the legs of walking robots. For further information, see papers by those authors, and more recently, others. In our group, we are working to miniaturize DEA actuators using conventional microfabrication techniques and materials. The main challenges are making compliant electrodes that are compatible with standard microfabrication methods, finding an elastomer that does not require pre-strain, depositing and patterning the elastomer, developing a successful surface micromachining process sequence, and powering the actuators. Efforts and progress towards these goals are summarized below. Volume Change Mechanism These devices, as do many other EAPs, also function as sensors: the capacitance across the electrodes changes upon stretching. (See for example Pelrine & Kornbluh et al., MEMS 97, Nagoya, Japan, Jan. 26-30, p. 238.) Closed-loop control is therefore possible. Clearly, carbon grease and carbon powder cannot be used in microfabricated devices. These materials are even problematic on the macro-scale, since they rub off. Thus, one of the most challenging aspects of miniaturization is the realization of compliant electrodes that can be fabricated using entirely standard microfabrication methods. One way of making compliant electrodes is based on Pt salt reduction. This work was inspired by the way that electrodes are formed on the faces of ionic polymer metal composites (IPMCs), which are a member of the ionic EAP family. The procedure is to mix the salt, Pt[NH3]4Cl2, into a photo-curable elastomer precursor (such as Loctite 3108), expose the precursor, and then reduce the salt chemically to form Pt metal. This method works because the salt is transparent, and thus does not interfere with UV exposure. After reduction, the material becomes shiny and gray.

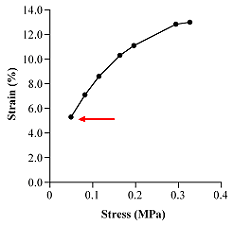

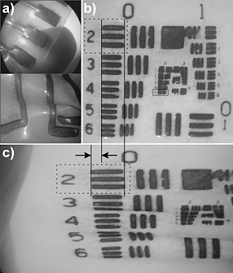

For further information, see: M. Urdaneta, R. Delille, and E. Smela, "Stretchable electrodes with high conductivity and photopatternability," Adv. Mater., 19 (18), 2629-2633. R. Delille, M. Urdaneta, K. Hsieh, and E. Smela, "Compliant electrodes based on platinum salt reduction in a urethane matrix," Smart Mater. Struct., 16 (2), S272 -279 (2007). R. Delille, M. Urdaneta, K. Hsieh, and E. Smela, "Novel compliant electrodes based on platinum salt reduction," SPIE 13th Annual Int'l. Symposium on Smart Structures and Materials, EAPAD, San Diego, CA, (SPIE), vol. 6168, edited by Y. Bar-Cohen, p. 61681Q-61681 -61611 (Feb27 - Mar 2, 2006). An issue that must be addressed when miniaturizing is prestrain. Most elastomers must be stretched, typically over a frame (see for example the 2nd figure on the site of Dr. Jim Hubbard – without this prestrain, they do not actuate when a voltage is applied and/or they suffer failure due to pull-in. However, prestrain is incompatible with microfabrication techniques. Poly(dimethylsiloxane), PDMS, can be used without prestrain, and is also a standard MEMS material. We are characterizing the actuation behavior of PDMS, as well as developing methods for patterning it, and for patterning electrodes on it (see figure). We are able to obtain 5% strain without pre-strain (see figure), which is already quite useful.

When surface micromachining a DEA, the elastomer is spin-coated onto the surface to form a thin film, and it must then be patterned. Methods such as molding, used to form thicker free-standing structures, would not be appropriate. Graduate student Bavani Balakrisnan has developed a technique for etching PDMS that combines dry etching to achieve a high aspect ratio followed by wet etching to remove the final few microns of material without attacking the Si substrate.

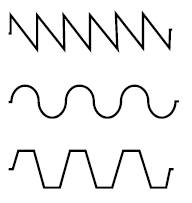

Compliant elements in microscale applications include meandering beams, crenellated surfaces, and zigzag-shaped electrodes. There are general guidelines for designing such meandering cantilevers - the roles of meander amplitude, angle, length, and thickness in determining axial and bending stiffnesses can be understood without running simulations for each case. The more complex case of a stiff thin film overlying a crenellated elastomer has also been studied.

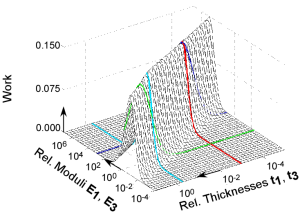

The bending of multi-layer actuator structures has also been studied, yielding guidelines for achieving maximimizing bending angle, force, or work. The results are applicable to actuators such as dielectric elastomer actuators, conjugated polymer actuators, IPMCs, piezoelectric stacks, and so on. We have made available a Matlab program that allows users to enter their own device parameters to estimate performance metrics, or to explore the space of possible designs without the need to run FEA simulations on each case. To obtain it, go to the supporting information for the paper, on the Publications page.

Background | Compliant Electrodes | PDMS as an Elastomer

|

Page last updated: August 10, 2015

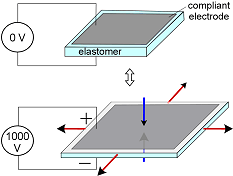

The actuation mechanism is illustrated here. A stretchable (elastomeric) dielectric film (e.g., like a rubber) is sandwiched between stretchable (compliant) electrodes, generally carbon grease or carbon powder. When a high voltage is applied across the electrodes, they are attracted together by the electrostatic force, and they squeeze the elastomer laterally. This lateral expansion is large (depending on the elastomer, one can get a 100% increase in area), and this can be used for actuation. (See "High-speed electrically actuated elastomers with strain greater than 100%," R. Pelrine, R. Kornbluh, Q. B. Pei, and J. Joseph, Science, 287 (5454), 836-839 (2000).) Of course, one trades off strain against force. The actuation is fast, like that of other electric-field driven actuators, since it does not depend, as the ionic actuators do, on mass transport.

The actuation mechanism is illustrated here. A stretchable (elastomeric) dielectric film (e.g., like a rubber) is sandwiched between stretchable (compliant) electrodes, generally carbon grease or carbon powder. When a high voltage is applied across the electrodes, they are attracted together by the electrostatic force, and they squeeze the elastomer laterally. This lateral expansion is large (depending on the elastomer, one can get a 100% increase in area), and this can be used for actuation. (See "High-speed electrically actuated elastomers with strain greater than 100%," R. Pelrine, R. Kornbluh, Q. B. Pei, and J. Joseph, Science, 287 (5454), 836-839 (2000).) Of course, one trades off strain against force. The actuation is fast, like that of other electric-field driven actuators, since it does not depend, as the ionic actuators do, on mass transport.

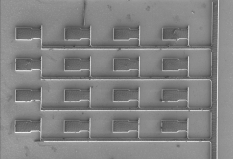

This procedure results in a highly conductive metal skin on the surface of the elastomer. The big advantage of this approach is that, unlike when adding conductive fillers, the Young’s modulus does not go up: the composite has the same modulus as the original elastomer. The other significant advantage is that the electrodes can be patterned, as shown in this figure.

This procedure results in a highly conductive metal skin on the surface of the elastomer. The big advantage of this approach is that, unlike when adding conductive fillers, the Young’s modulus does not go up: the composite has the same modulus as the original elastomer. The other significant advantage is that the electrodes can be patterned, as shown in this figure.