|

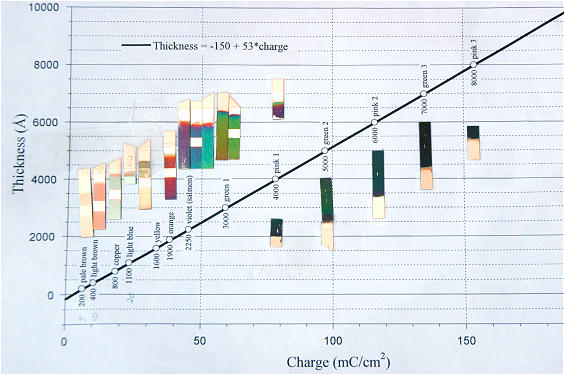

Fabrication Bilayers | Self-Folding Boxes | Moving Si Plates | Origami Flower | Thickness Color Chart Polymer Deposition Conjugated polymers can be deposited in a variety of ways, but are typically deposited electrochemically or by spin coating or casting. For a chart showing the color of PPy(DBS) as a function of film thickness, see below. For further information, see: "Microfabrication of PPy microactuators and other conjugated polymer devices," E. Smela, J. Micromech. Microeng, 9, 1-18, 1999.

For further information, see: "Controlled Folding of Micron-Size Structures," E. Smela, O. Inganäs, and I. Lundström, Science, 268(5218), 1735-1738, 1995.

For details, refer to: "Electrochemically Driven Polypyrrole Bilayers for Moving and Positioning Bulk Micromachined Silicon Plates," E. Smela, M. Kallenbach, and J. Holdenried, J. Microelectromechanical Systems, 8(4), 373-383, 1999.

The color of PPy(DBS) deposited on Au changes as it increases in thickness up to ~1 mm (after that it appears black), as shown in the color chart below. The color is therefore a good indication of the thickness. Bear in mind that the colors shown here are for dry films, and will be different from what you see when the films are immersed, or recently removed from water.

|

Related Items

|

|

|

©2013

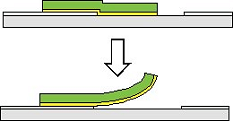

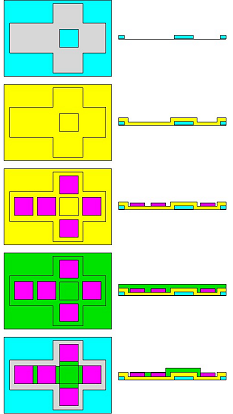

These were also made using surface

micromachining and differential adhesion was used for release.

These were also made using surface

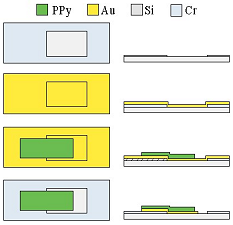

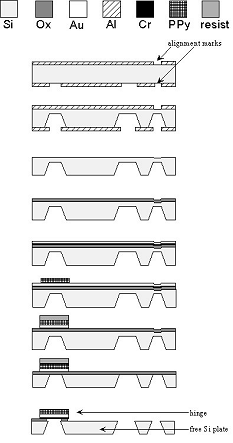

micromachining and differential adhesion was used for release. Bulk micromachining was used for

these devices. Al was sputtered onto both

sides of the wafer and patterned using a double-sided aligner. Reactive ion

etching (RIE) defined the plate, and the etching was halted with a thin layer

of silicon remaining. The Al was removed and an oxide deposited by chemical

vapor deposition (CVD).

Bulk micromachining was used for

these devices. Al was sputtered onto both

sides of the wafer and patterned using a double-sided aligner. Reactive ion

etching (RIE) defined the plate, and the etching was halted with a thin layer

of silicon remaining. The Al was removed and an oxide deposited by chemical

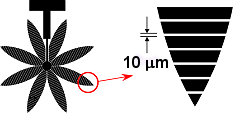

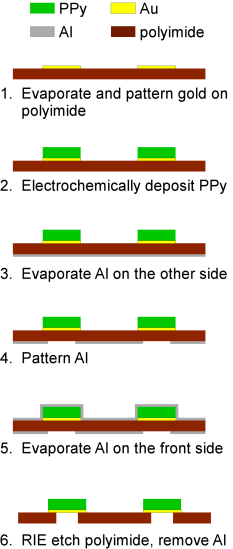

vapor deposition (CVD). These structures were made using bulk micromachining, like the moving Si plates. The close-up schematic below shows how each petal was contructed from numerous parallel polyimide plates connected by long, thin bilayers.

These structures were made using bulk micromachining, like the moving Si plates. The close-up schematic below shows how each petal was contructed from numerous parallel polyimide plates connected by long, thin bilayers.